The most critical one likely being where you have the boards produced.īe sure to download your free PDF guide 15 Steps to Develop Your New Electronic Hardware Product.

The cost you will pay for prototypes of your Printed Circuit Board (PCB) will depend on many variables. This is especially critical if you don’t have the experience to judge their quality of work.įor most products you will need at least an electronics engineer, a programmer, and a mechanical engineer. Regardless of their location or experience level you should always have other independent engineers review their work along the way. typically much cheaper with hourly rates varying from $25 to $75 per hour. You can hire engineers outside of the U.S. can vary from $50-$300/hr. This is a big variance but once again it all depends on the experience level of the engineer.įor example, a more expensive engineer may be able to work twice as fast and produce a higher quality of work, both of which will lower your overall cost. Roughly, hourly rates for an engineer in the U.S. The hourly rate charged by design engineers varies depending on location, years of experience, education level, area of specialty, success with previous projects, etc.Īccording to the Institute of Electrical and Electronic Engineers (IEEE) the average rate for an independent contract engineer is $125/hr. So you should expect your costs to exceed what is initially estimated. Most engineers work on an hourly basis especially on larger projects.īe warned though that it’s impossible to quote the development time for a complex product exactly down to the hour.

#A prototype is full#

This is why I recommend working with experts independent of your primary developers to help simplify your product before you begin full development. The more complex the product the more money they get paid. Keep in mind that asking your primary developer to help simplify your product creates a conflict of interest. This small change likely lowered his prototype cost by about 3 times! You know what? This feature wasn’t even essential and we were able to suggest a much more feasible solution.

Immediately we explained to him there was one product feature that was driving up all of his costs including his development, prototyping, electrical certifications, and injection mold costs. This entrepreneur was quite technical and had thought a lot about the product details.īut, he didn’t understand all the future consequences of the features he had specified. Reducing product complexity drastically reduces all of these costs making it more feasible to bring the product to market on a restricted budget.Īs another example a member in my Hardware Academy recently shared his product details to get feedback from myself and the other experts. This includes costs like electrical certifications and injection molds. Many times a seemingly “simple” feature can dramatically increase the development complexity and cost.Įven something as simple as the location of a button can cost you thousands of dollars extra down the road when it is time to purchase injection molds to mass manufacture the enclosure.ĭon’t forget all of the steps that lie beyond the initial prototype on the path to market.

Ultimately, the best way to reduce your prototyping cost (in fact, all of your costs) is to simplify your product as much as possible as early as possible. They also can vary greatly depending on several variables but especially on the product complexity.Įngineering fees may be only a few thousand dollars for a simple product up to hundreds of thousands of dollars for a really complex product.

#A prototype is plus#

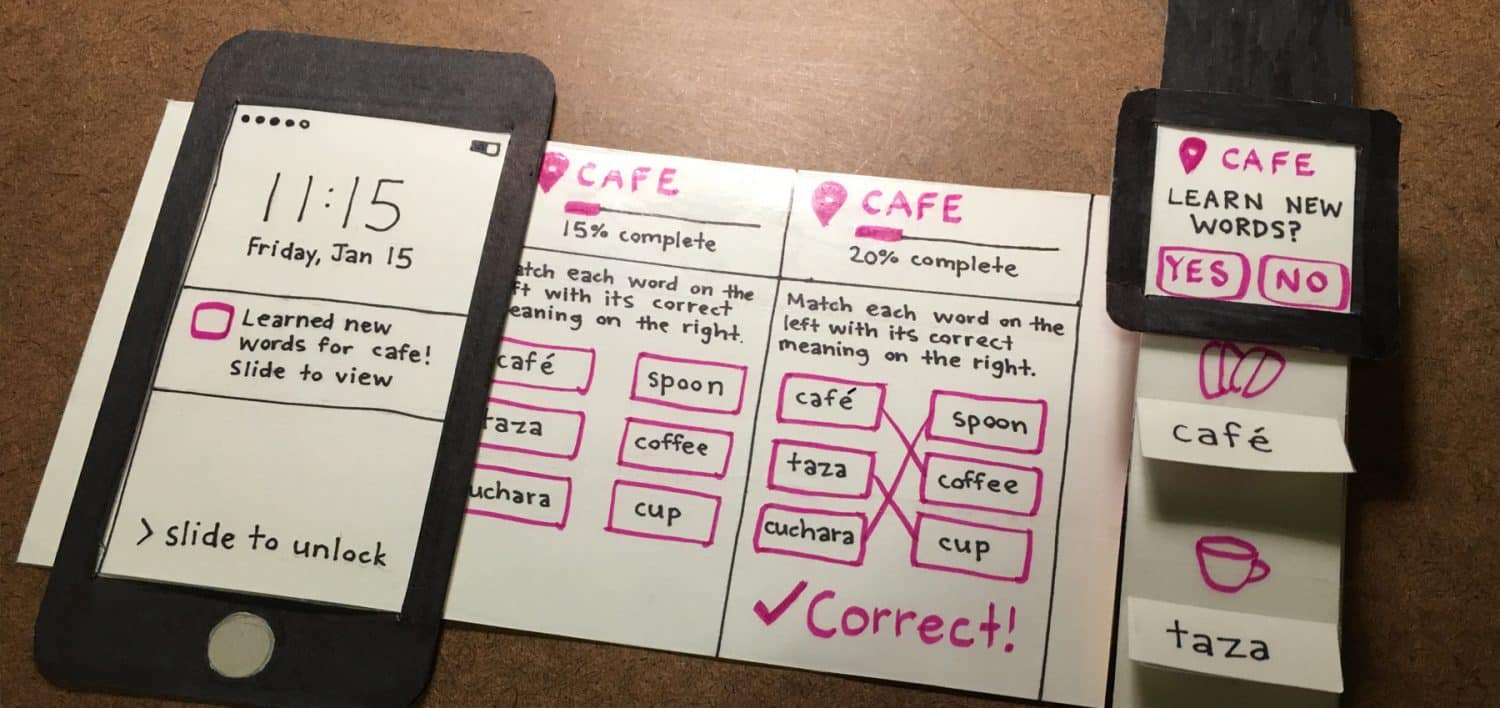

The total cost of the prototype (assuming an electronic product) usually includes the cost to manufacture the custom Printed Circuit Board (PCB), plus the cost of components, assembly, and the enclosure.įor most products the engineering costs will dominate. The cost of a prototype can be broken into two major parts: the engineering cost to design it, and the actual cost to produce it.

0 kommentar(er)

0 kommentar(er)